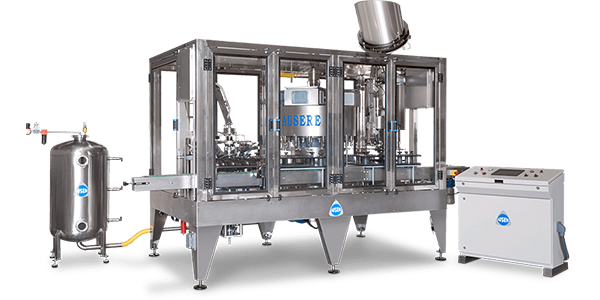

Fully automatic rotary machine to fill products with any viscosity and conductivity (STILL WATER, JUICE, OIL, DETERGENT,…).

Filling system by flowmeter:

Depending on the product, the high accuracy flowmeters could be mechanical by oval gears, magnetic or mass, with filling valves with a perfect opening and closing. The filling group consists of a control system and a flowmeter per each valve. The machine is equipped with a product tank to feed to valves by means of a manifold placed on the flowmeters. The system works without pressure in the bottle and with slight pressure in the tank. Due to the small number of its functional parts, the filling circuit can be cleaning easily.

Bottles go into the filling group by means of a starwheel and are clamped by a pliers at its neck. The dosing can be with distance from the neck or bottom-up, depending on the product is foamy or not.

- Tank, inlet pipe for product and filling valves are all made of stainless steel

- Safety protections made of methacrylate following the CEE Standards.

- Flowmeters does not need require and specific maintenance.

- Maximum filling accuracy: ± 1,5 grams per liter.

As for the closure on the bottles, an automatic capper can be mounted for pressure, screwed or aluminium (pilfer proof) caps thus forming a MONOBLOCK with the filler. The capper consists of an accumulating hopper for the caps, cap orientator, a chute and a wheel for pressure closures or a chuck heads group for threaded closures.

As with the monoblock, you can also include a blower/rinser thus forming a TRIBLOCK with a filler and capper as seen in the photo. This is a mechanical rotary machine equipped with the right number of heads to assure an optimal time period to adjust to the requirements. Both capping and blowing groups have included its motorized regulation system to adjust the height of the groups.

Optional Accessories:

- Caps Elevator.

- Production monitoring program.

- “No cap – no bottle” control system.

- Both the capper and blower/rinser can be purchased separately.

These machines can be equipped from 6 up to 70 filling valves depending on the speed requirements and product specifications.