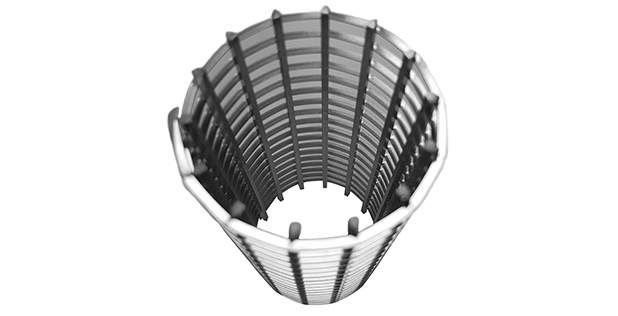

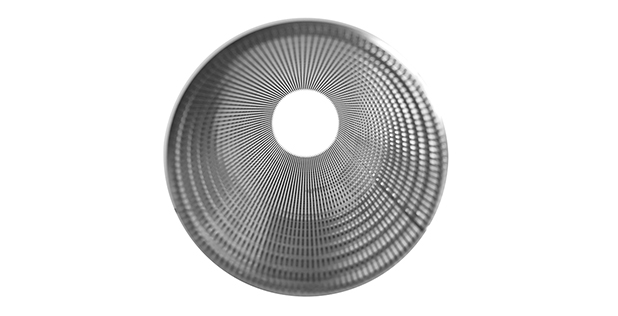

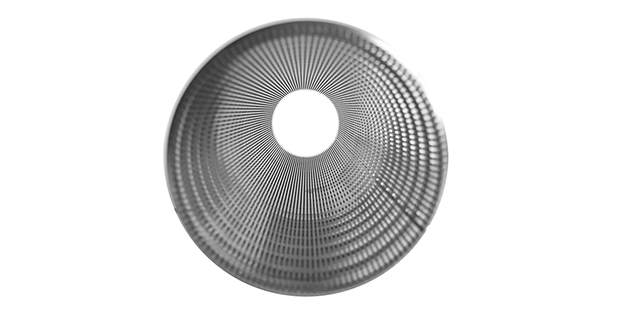

Our wedge wire filters, cylinders and slot tubes are made from our profile wedge wires. The wedge wires are rolled and welded to support rods at regular intervals. Therefore, giving maximum open area and strength offering optimum opportunity for filtration. We manufacture a wide range of profiles, support rod options, in addition to bespoke specification.

Wedge wire filters, cylinders and slot tubes are used for filtration of liquids in industries. For example; pharmaceutical, food and beverage, petrochemical and chemical, waste water treatment and backwash/cleaning systems. The profiled ‘v’ shaped wires give the wedge wire filters, a low risk of clogging in addition to a self cleaning effect.

We offer three different options when it comes to our wedge wire filters, cylinders and slot tubes:

Standard radial slot specification works by filtering from the outside to the inside. The profiled wire is welded to the support rod at the narrowest point, this gives the working outside a smooth surface.

Special radial slot specification works by filtering from the inside to the outside. The profiled wire is welded to the support rod at the widest point, as a result this will give an interrupted internal surface due to the support bars.

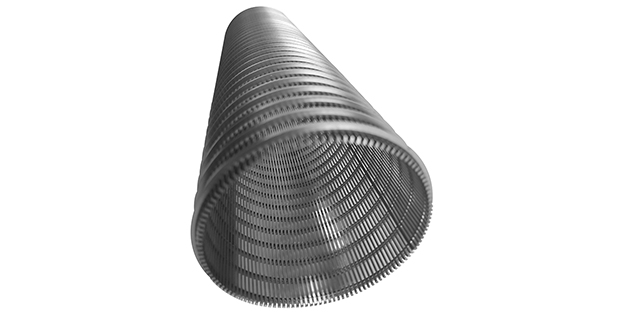

Axial slot specification works by filtering from the inside to the outside. The profiled wedge wires are run down the length of the tube and the support rods are then welded on the narrowest point of the wedge wire, therefore giving a smooth internal working surface. Furthermore, the support rods are welded to the outer surface of the wedge cylinder giving profiles which are pressure welded to form the connection.

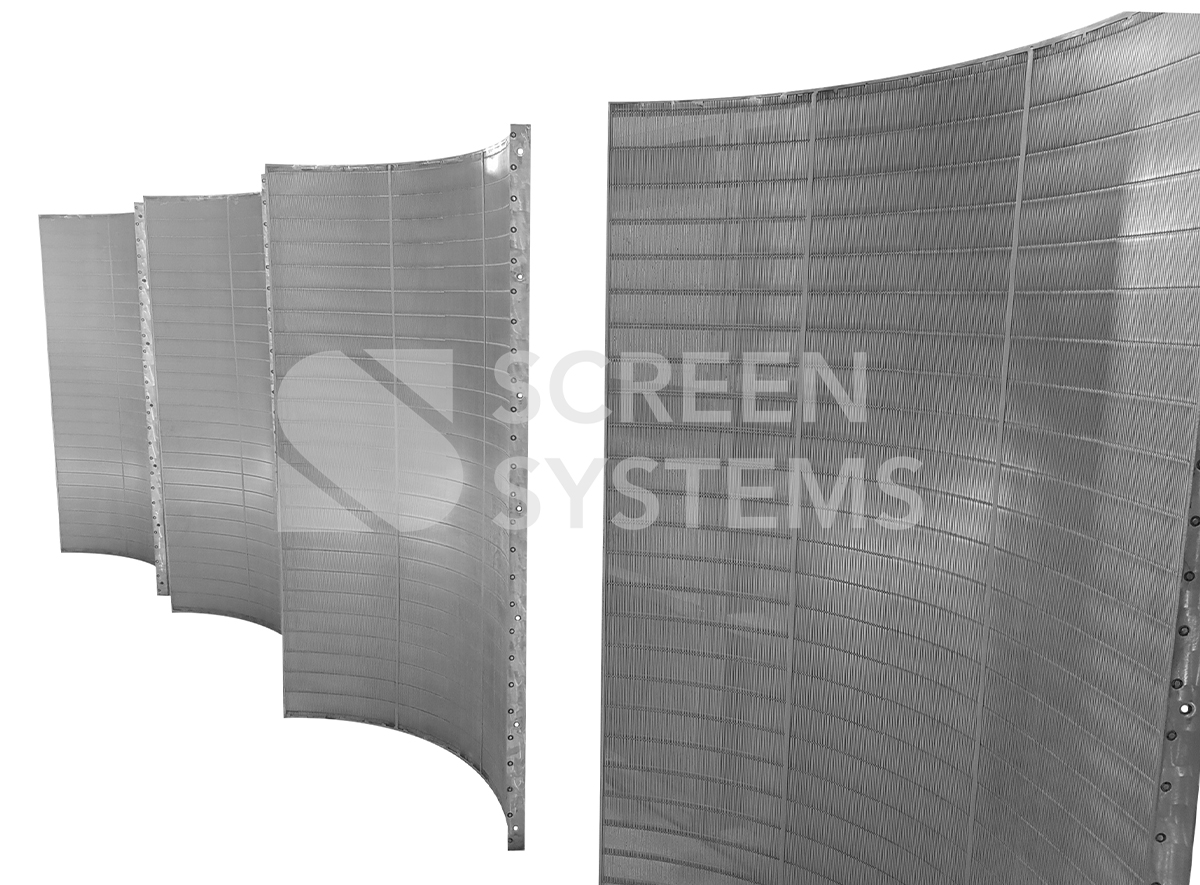

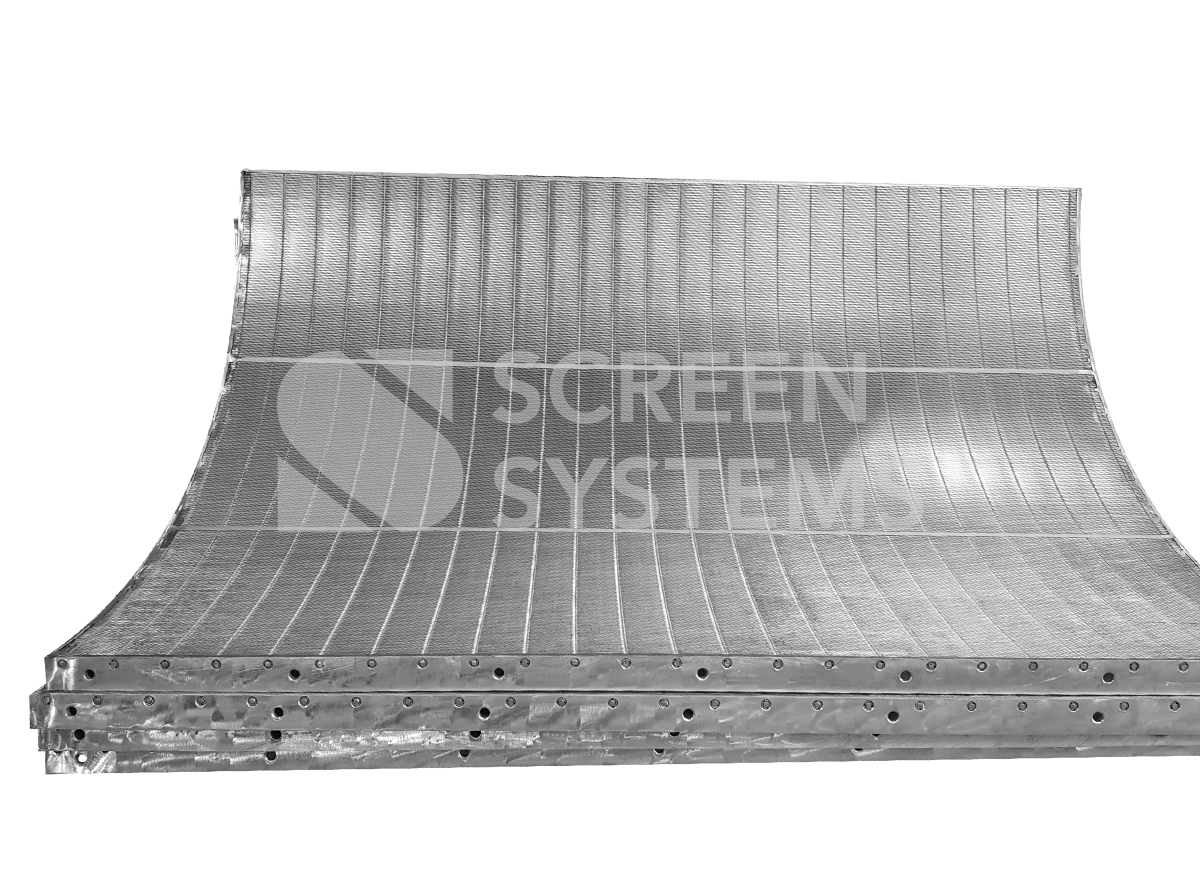

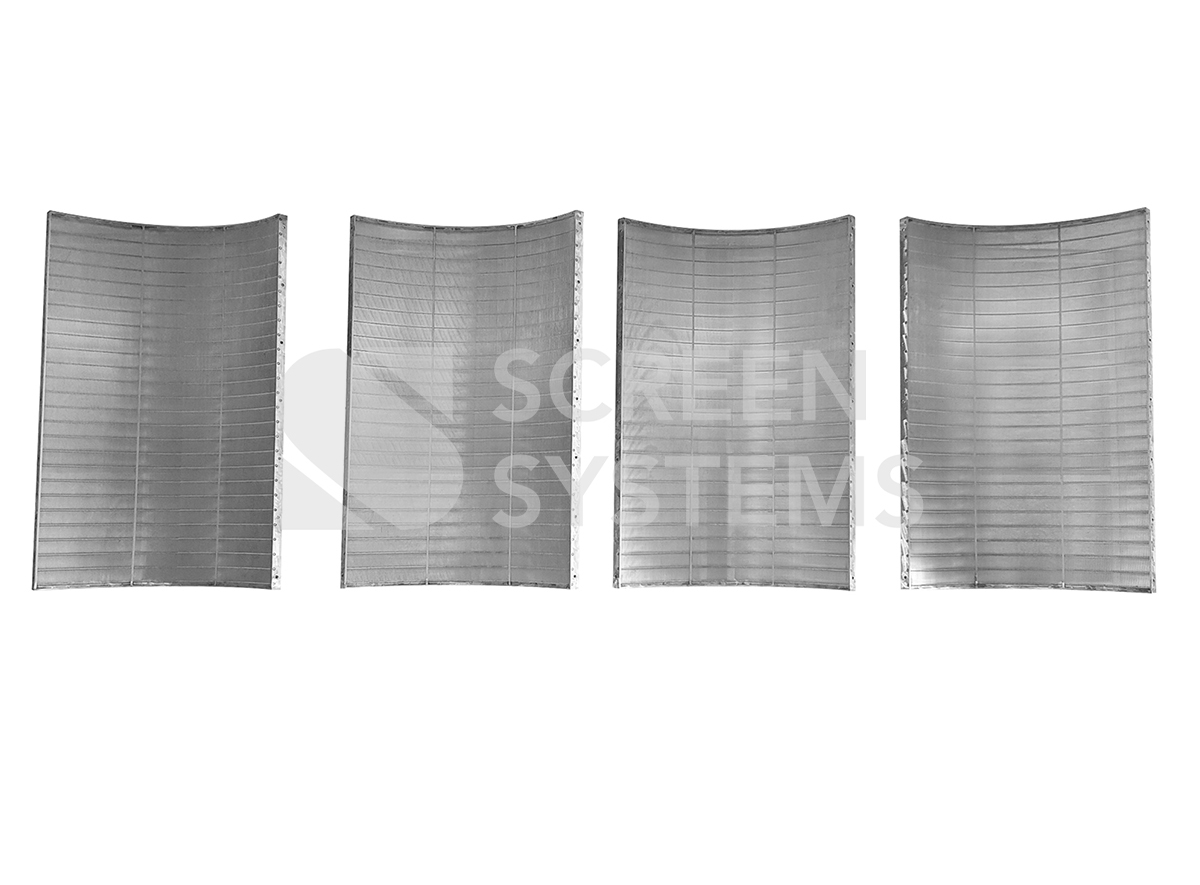

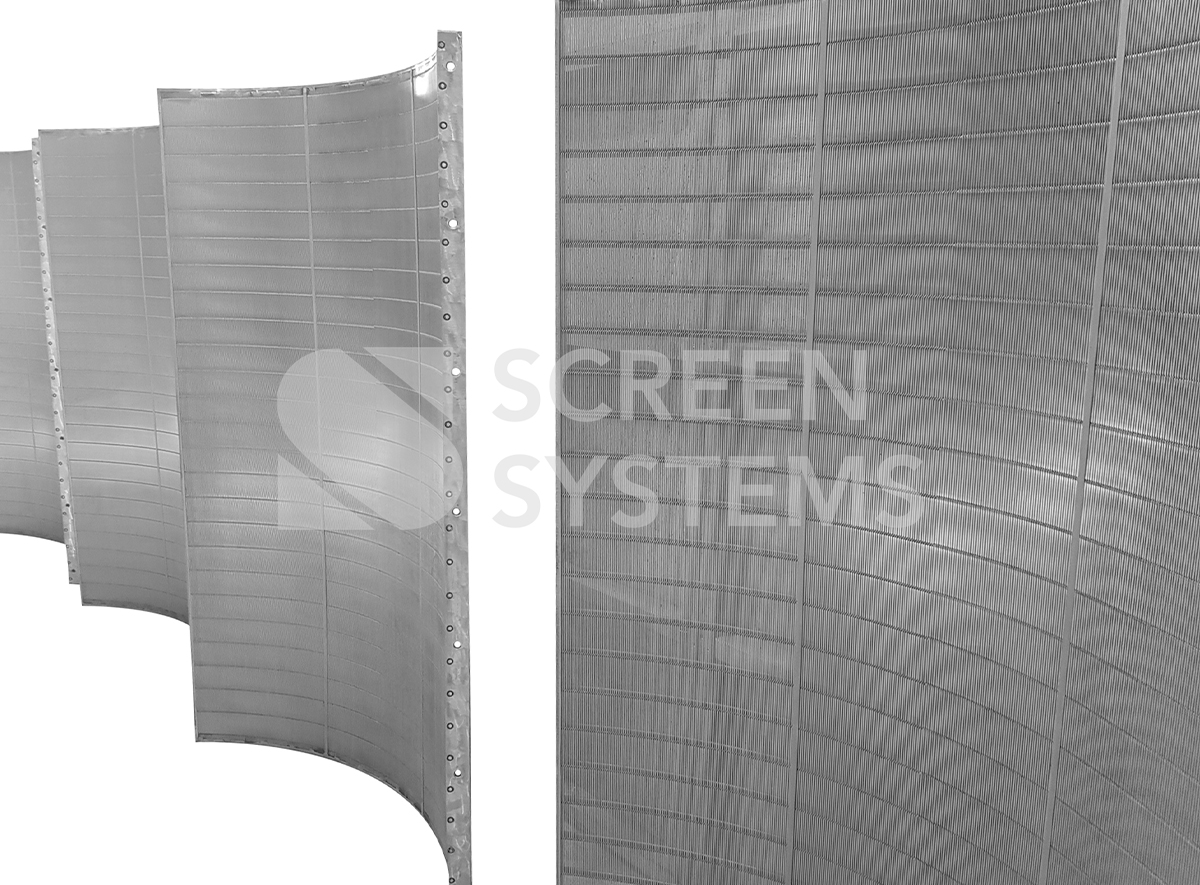

Screen Systems have recently completed a project for a large looped wedge wire cylinder. The cylinder will be used for the dewatering of parts in a rubber factory. Due to its size it was constructed in four sections. The inside diameter of the completed cylinder was 1,600 mm×1,800mm height, 20mm×10mm intermediate supports, 50mm×10mm flanges on each side, curved 50×10 on the ends of the cylinder, using looped wedge wire 32F with a 0.75mm gap.

Screen Systems project for a wedge wire cylinder used as a separator in a drainage channel in a food factory. The cylinder was created at 126mm long and 56mm O/D, made with Stainless steel 316L. In addition, it was open at both ends to be used as a separator in a drainage channel in a food factory.

Screen Systems recently completed a project for a welded wedge wire stainless steel dewatering screen. It was a welded wedge wire tubular filter with a 1mm aperture x 12SB profile. In addition, it was created using Stainless steel 304 and had external support rods, 12SB at approximately 12mm pitch plain cylinder.