Wedge wire trommel screens and rotary screening drums are mechanical screening machines used to separate materials. Wedge wire trommel screens are used in the mineral and solid-waste processing industries.

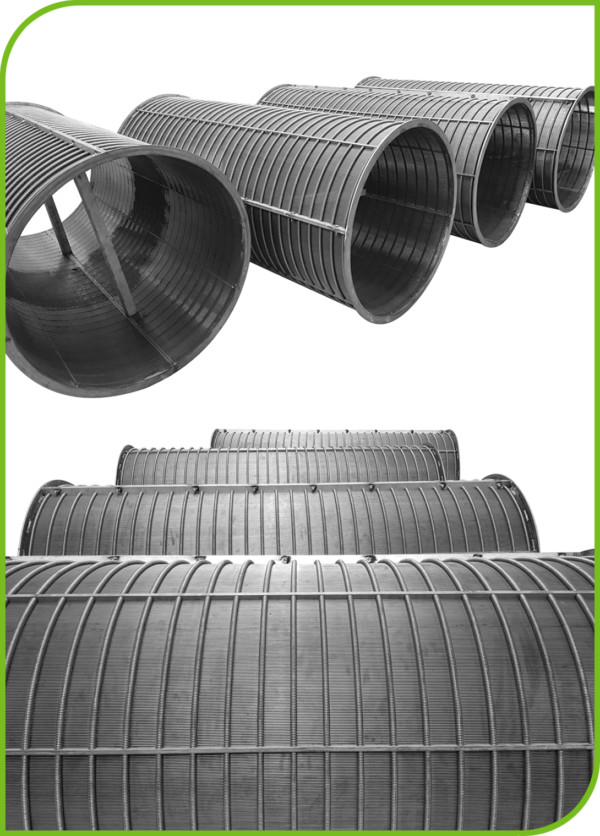

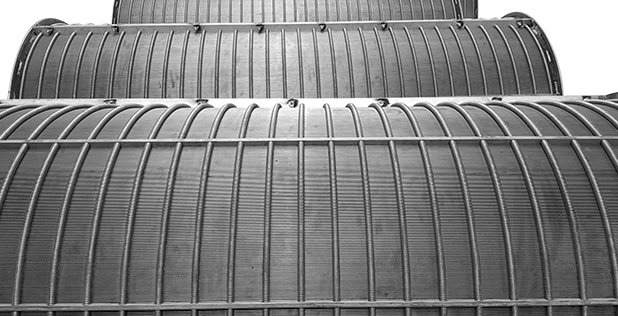

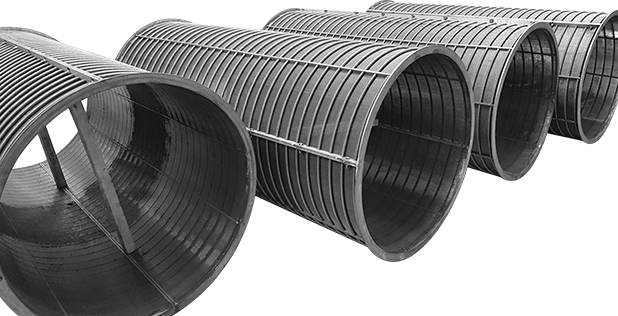

they remove fines from waste streams. The trommel consists of a wedge wire cylindrical drum (rotary drum) elevated at an angle at the feed end. Screen Systems looped wedge wire is an extremely robust and durable screening method product.

Material is fed into the trommel drum (rotary screening drum), then lifted up by the rotation and aerated as it falls back down. After that, this action is repeated with each revolution along the length of the drum. The smaller segments therefore pass through the screen openings. The larger fractions finally tumble towards its eventual exit at the rear of the drum. Wedge wire and looped wedge wire rotary drums are used for wash plant applications including mineral extraction plants, coal mining and fibreglass processing operations. In addition, food washing factories and many more.

A trommel drum cylinder separates materials by size, and also used for separating biodegradable fraction of mixed urban waste, including separating different sizes of crushed stone. In addition, contractors screen their site debris into two segments. A saleable topsoil for farms, nurseries and site-work for example, and, rock cleaning for aggregates and landscaping work. As a result, contractors resell their waste, instead of incurring disposal costs.

Note – Our rotary screening drums are supplied hollow, customers install their own internal fixings.

Screen Systems recently completed a project for wedge wire trommel screens for dewatering/purifying. Wedge wire trommel screen, 0.55mm aperture (tyler mesh #30), X profile 32f, Cylinder 2250mm long x 1000mm i/dia. The screen face on the inside was made in 2 halves bolted and welded together, each half with 40x10mm joining bars and 3-off 20×10 st/st intermediate bars. In addition, titted with 40x8mm st/st 304 undrilled flange ring at each end also fully weld wires end and ring flush.