The IND570 is an advanced industrial weighing terminal designed for a broad range of manual and automated weighing applications. The terminal combines flexibility in connectivity and control options with advances in performance verification and secure access to critical process data to provide the measurement accuracy, reliability, efficiency and traceability required today.

| Resolution | 100,000 displayed divisions |

| Resolution (approvable) | NTEP Class II 100,000d, Class III/III: 10,000d, CoC 13-123 OIML R76 Class II approved divisions determined by platform, Class III and IIII 10,000e, TC8458 |

| Measurement parameter | Canada Class II 100,000d, Class III 10,000d, Class III HD 20,000d, AM-5593 |

| Dimensions | Harsh: 265 mm, 148.4 mm, 163 mm (10.4 in. 5.8 in. 6.4 in.) |

| Housing Harsh/Desk-Column-Wall mount | Stainless steel, includes brackets for wall mounting |

| Panel | Stainless steel faceplate, aluminum chassis with integrated mounting brackets |

| Degree of protection | Harsh: IP69K, Panel: IP65 |

| Keyboard | 26-key tactile keyboard, alpha-numeric keypad, scale function keys, softkeys and navigation keys for applications |

| Display | 146 mm (5.75”) high-resolution, high-contrast, graphic OLED, 25mm high weight display. OLED technology lowers power consumption. |

| Mounting options | Panel, desk, wall, column |

| Suitable platforms / weigh modules | A/D >366 Hz, supports 1- 12 350 Ohm analog load cells, 2mV or 3mV. Digital: Supports a single SICSpro or IDNet platform. POWERCELL: Supports network of up to 14 POWERCELL load cells |

| Digital Input/Output | Internal: 5 inputs, 8 outputs, dry contact relay, or: External: Up to 3 ARM100s, 4 inputs, 6 outputs each |

| Interfaces | USB host; RS-232/RS-422/RS-485 serial port |

| Options | Ethernet TCP/IP; COM2/COM3 serial ports; Analog Output; ControlNet; DeviceNet; EtherNet/IP; Modbus TCP; PROFIBUS DP, PROFINET |

| Applications | Basic weighing; static checkweighing; single material filling or dosing; Alibi memory; storage tables for materials and containers; operator prompting; easy USB file transfer; 10 customizable templates for printing |

Features & Benefits

- Options for a perfect fit: Highly versatile in form and function, the IND570 is designed for uncomplicated integration into weighing applications from basic to sophisticated.

- Performance monitoring: Integrated system performance monitoring includes GWP®. User-friendly diagnostic reporting uses an integrated email function. Embedded InTouchSM for active monitoring of equipment with optional InTouch Remote Support services available only from METTLER TOLEDO. These features combine to help keep the IND570 weighing system running at maximum potential.

- Flexible control options: Implement customized operator routines to guarantee consistency in manual processes, or allow the IND570s standard applications, fast updating discrete I/O and PLC communication to take control of a process. The IND570 offers the flexibility to best utilize available resources.

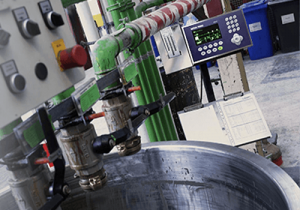

- Ready for filling and dosing: Offering easy-to-configure software routines, discrete I/O, material storage tables and more, the IND570 is ready to work as a highly accurate controller for simple or sophisticated blending, filling and dosing operations.