The ability to monitor and control up to 4 scales with independent scale settings, an advanced database for managing store tare & target values, plus thousands of weighing records which can then be exported into higher level applications is the core of an advanced terminal that has the flexibility needed to integrate into a broad variety of weighing applications.

Sophisticated Material Transfer Control for Optimum Manufacturing Performance and Best Practices:

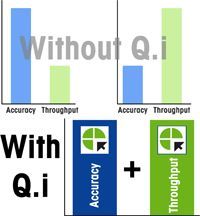

- Improve material feed accuracy

- Increase manufacturing capacity

- Minimize production cost

- Ensure best practices regardless of host PLC or DCS platform

The IND780 Q.iMPACT terminal features:

The IND780 Q.iMPACT terminal features:

- Patented auto-tuning capability with exclusive feed algorithms – proactively corrects for material feed variation during each feed

- Overlapping Feeds and single speed, on-off control – significantly reduce capital expenditures

- Batching, blending, filling, dosing & formulation processes – all benefit from the advanced Q.iMPACT material transfer control

- Flexible terminal clustering and systems comprising up to 198 scale and flow meter combinations – match any system size, ready for system expansion

- Significantly reduce costly raw material over-feed and unacceptable raw material over-feed – reduce off-spec product and bring new products to market more quickly with Q.i

- Up to 999 configurable material pathsper IND780 terminal – for system flexibility, ease of expansion and rapid product testing and evaluation

- Dedicated PC-based configuration tool – eases set-up and configuration of scales, flow meters, load cell systems and process I/0

- Multiple field bus options – connect to any popular PLC or DCS platform, with common Q.iMPACT advanced feed control