METTLER TOLEDO weighing terminals deliver unequalled performance, flexibility and ease of use. From basic weighing needs to advanced integration with numerous scales, software, and accessories, METTLER TOLEDO vehicle scale terminals offer high-quality controls for your weighing operation.

| Level | Transaction |

| Display | Graphic LCD, transflective/backlit, 240 x 96 pixels |

| Interfaces | Serial, USB, Ethernet, Digital I/O |

| Degree of protection | IP66 |

| Housings | Stainless steel |

| Applications | Animal Weighing, Checkweighing, Counting, Peak Weight Measurement, Vehicle Weighing |

| Suitable platforms / weigh modules | Analog load cells, POWERCELL load cells |

| Digital Input/Output | Optional, 2 inputs, 4 outputs |

| Mounting options | Fixed wall brackets (standard on Analog version, optional on POWERCELL version); tilt/swivel bracket (optional) |

| Accessories | SD memory card (Analog version), MicroSD card (POWERCELL version), NiMH Battery Pack, NiMH Battery Pack Charger |

| Power Supply | 100 – 240 VAC or NiMH battery |

The IND246 comes pre-configured with five transaction weighing applications ready to use:

- Animal Weighing: Generates average weight for one animal, or average weight-per-animal for multiples

- Counting: Prompts operator through piece counting sequence to help reduce operator errors. Includes continuous automatic reference optimization and accumulation by part ID

- Checkweighing: Over/Under operation with clear on-screen status display, and two selectable sizes of SmartTrac graphical representation

- Peak Weight Measurement: Displays the peak weight from the current weighing cycle, or maximum, minimum and average peak weight from a multi-transaction weighing cycle

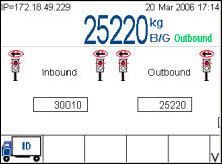

- Vehicle Weighing: Temporary or Permanent ID weighing for one- and two-pass operation