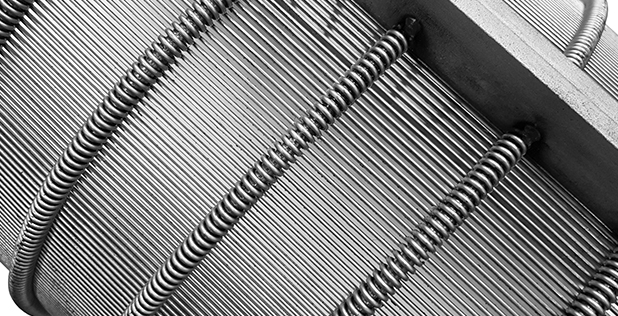

Looped wedge wire screens separate materials such as solids from liquids, and smaller materials from bigger materials. Individual wires are put through a machine, looped at 70 mm and held together with cross rods.

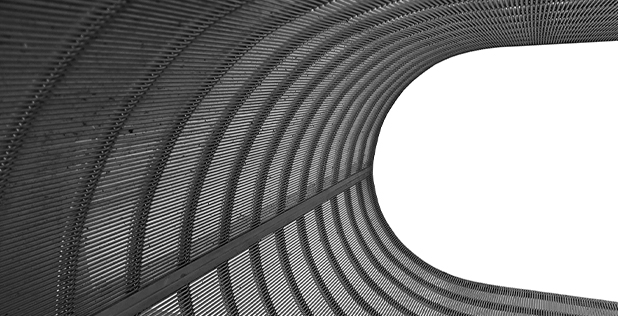

Screen Systems have recently completed the production of a curved looped wedge wire screen for the coffee bean industry. The screen was designed and manufactured at the dimentions of 1.5mm (AP) x 70mm. 28F looped wedge wire was used. The wire diameter was 2.35mm from 304 stainless steel. The cross bar was 7.7mm while the side plate was 50mm x 10mm.

Screen Systems have recently completed the production of a curved looped wedge wire screen for the coffee bean industry. The screen was designed and manufactured at the dimentions of 1.5mm (AP) x 70mm. 28F looped wedge wire was used. The wire diameter was 2.35mm from 304 stainless steel. The cross bar was 7.7mm while the side plate was 50mm x 10mm.