Engineered for the Food, Specialty Chemical, Plastics, Glass and Aggregates batching and formulation market, the IND780batch works as a stand-alone terminal for single scale, multi scale, or flow meter applications.

Engineered for the Food, Specialty Chemical, Plastics, Glass and Aggregates batching and formulation market, the IND780batch works as a stand-alone terminal for single scale, multi scale, or flow meter applications.

Feed the Exact Amount of Material in the Shortest Amount of Time, Every Time With Q.impact the terminal becomes the ideal controller to master the feed measurement, management and cutoff portion of batching, blending, filling, dosing or formulation processes.

When verifying inventory, packing parts in containers or confirming production quantities, every part is important. METTLER TOLEDO is the leader in precision parts-counting technology, ensuring that only the right number of parts are delivered to you or your customer. We provide counting solutions with all levels of accuracy and functionality to make parts-counting solutions simple and cost effective.

The full-line of METTLER TOLEDO counting scales gives you mobility, full barcode scanning and printing, a database configured to your specific needs, as well as full communication to your inventory/logistics planning and management systems. Sampling methods, operator messages and automatic accuracy improvements are user configurable.

The accuracy of METTLER TOLEDO’s measurements is supported by a wide variety of communication standards as simple as USB, RS232/485 or 4-20ma or more complex Industrial communication busses such as Profibus®, Ethernet/IP, DeviceNet® and ControlNet®. Ethernet binds many of our data/operator intensive counting, formulation and inventory control workstations to your network. It is just not the physical connection; our products provide you with the precise measurement and we give you the extra information you need to run you business/process. We also support communication of diagnostic information, helping your anticipate problems, identify changes made to the configurations and maximize asset utilization. METTLER TOLEDO strives to give you the traceability, transparency and accuracy you need by talking your language through many industrial standard interfaces.

Software

SoftwareData can be collected in real time via an automatic print event by the terminal, a scheduled transmission of data, or on demand via a manual command,

Measuring technologies with versatile connectivity to Siemens PLC Systems enables you to select the right terminal, or transmitter, for connection to a vast number of precision scales, weigh modules or sensors

When filling Intermediate bulk containers, totes, drums or big-bags you need very fast, precise, and repeatable results. METTLER TOLEDO high-performance weighing terminals connect with high precision scales, weigh modules and load cells providing you unmatched accuracy. Connectivity to most automation fieldbus networks is offered. METTLER TOLEDO weigh modules and precision measuring cells provide the broadest product offering, and rugged design.

Filling of vials, tubes and syringes in manufacturing of pharmaceuticals and in cosmetics as well as filling of numerous samples in research requires compact but very accurate weigh modules. Modern high-precision weigh modules from METTLER TOLEDO offer ultra-small footprints, which makes them easy to integrate so that they fit seamlessly into instruments and automated weighing stations.

Automated gravimetric filling of high viscosity liquids such as edible oil and cosmetics is done on rotary or linear machines with arrays of weigh modules to fill several bottles in parallel. METTLER TOLEDO weigh modules are tailored to the needs of machine builders. They are designed for easy mechanical, electrical and software integration.

When you fill tons of product into a truck or railcar, measurement accuracy is critical. Unlike flowmeters, weighing ensures you are not giving away expensive product or overcharging customers. Our truck and rail scales can be easily integrated with your filling systems for unsurpassed accuracy and confidence in all of your transactions.

Simple Formulation

Simple FormulationA repeatable formulation process starts with accurate weighing. Simple paper-based operations can be enhanced with scale terminals that feature visual tolerance indication with weighing bars and color displays. Documentation and traceability are achieved by attaching a printer to record actual material quantities.

Scale terminals with integrated recipe management provide an additional level of process control in a compact package. Raw materials, lot numbers, and operator messages can be stored for easy operator recall. Confirmation of process steps with a connected barcode reader ensures the production is both comfortable and secure.

Whether production requires manual or automatic dispensing, or a combination of the two, centralized formulation systems can unite workplace flexibility with rigid process control. Configurable software and operator friendly workstations can optimize the weighing process to eliminate errors, streamline utilization, and reduce material waste. Incorporation of industry standards, such as S88, integration with ERP systems and validation support for regulatory environments ensure a complete and robust solution.

Accurate and consistent filling, dosing and batching are essential to ensure consistently high product quality. When choosing the right weighing equipment for hazardous areas, the correct classification and the appropriate method of ignition protection must be considered. Installing intrinsically safe weighing instruments ensures accurate and reliable weighing results at highest protection levels.

Intrinsically safe weighing equipment is ideal for weighing in hazardous areas because it keeps the entire system safe – independent from the weighing application. Intrinsically safe technology prevents explosions by ensuring that the energy transferred to a hazardous area is well below the energy required to initiate an explosion. Intrinsically safe systems allow equipment to be used without risk of igniting any flammable gas, dust or fibers that may be present in hazardous areas.

Choose from a wide range of compact, bench and floor scales, load cells, weigh modules and vehicle scales. Our intrinsically safe weighing terminals provide the functionality you need - from manual basic weighing applications to semi- or fully-automated process control. Standard communication interfaces enable seamless integration into your process environment. Furthermore, our products offer the flexibility of mobile battery operation.

Our experienced, factory trained specialists help you select the right weighing solution that matches your requirements and complies with the relevant hazardous-area regulations. In addition, our comprehensive service program will help you maximize the return on your investments. Keep your equipment operating to the best of its abilities and rely on our qualified support when and where you need it.

Intrinsically safe technology provides a flexible and modular solution to most industrial applications within hazardous areas. It is possible to communicate with multiple components through specially designed communication elements. One of its greatest benefits is that intrinsic safety enables equipment maintenance within hazardous areas, without the need to interrupt the power supply and to obtain a gas clearance certificate, which is necessary with open flame-proof equipment. This especially applies to instrumentation because fault finding on de-energized equipment is more complex and time-consuming.

In-line checkweighing helps prevent underweight product from being shipped and minimizes the risk of costly overfill. Dynamic weighing solutions help enhance productivity and profitability for manufacturers in the food and beverage, chemical, pharmaceutical and other non-food industries. Our solutions meet or exceed HACCP, NEMA 4X and various hygienic standards.

Distributors and eBusinesses weigh each parcel after order-picking to verify that all parts are inside. To do so, they store the individual weight, including tolerance, of each product and all packaging material in their database. With these values, they calculate the weight for each shipment and verify it on an in-motion scale. METTLER TOLEDO has a comprehensive range of standardized in-motion scales, but also weigh modules and platforms for customized solutions.

In any production, manual checkweighing is a common final control check to make sure customers receive the exact amount of product indicated on the label. Usually, manual checkweighing is a repetitive task and an operator is under constant time pressure to ensure all products are within a pre-defined weight range. METTLER TOLEDO provides different manual checkweighing scales, offering improved process accuracy, speed and ergonomics.

The operator places the item on the scale and checks if the displayed result is within the expected tolerance range. METTLER TOLEDO portioning scales and checkweighers are available in numerous sizes for ergonomic working. They help the operator increase process efficiency up to 20 percent with the colorWeight® function.

For portioning, prepared product is stored in a tray beside the scale. The operator puts an empty container on the scale, tares it and starts portioning. Once the defined tolerance range is reached, the operator removes the full container, puts on an empty new container, tares the scale and starts working on the next portion. Dedicated portioning scales offer functions such as “auto-tare” to tare individual container weights.

In the take-away operation, bulk products are placed in a tray on the scale. After activating the take-away mode, the operator takes away handfuls or scoops of product and fills smaller packages with a predefined amount of product. The scale automatically indicates optically if the amount in the hand or scoop is within tolerance and automatically resets the display. This speeds up the procedure without a keystroke from the operator.

Checking quality by weightis a versatile, accurate alternative to check the quality of a wide range of products in the metal, plastics and electronics industry. Completeness of kits, packages or shipments can be checked. Length of cables, application of coatings and completeness of assembly also can be monitored by looking at weight deviations. The verification of products or samples is done manually with traditional checkweighing. The colorWeight® mode allows high throughput and error-free processes.

METTLER TOLEDO delivers accurate and reliable results for simple weighing and counting tasks. Check more products in a given time, count exactly, ensure completeness of packages or check whole pallets for their weight quickly with scales dedicated for those basic applications. Benefit from durable construction for long-lasting operation in industrial wet and dusty environments. Meet your everyday weighing requirements and fulfill both local weights and measures regulations and your internal quality standards. Our reliable and rugged weighing instruments are suitable for food, chemical or manufacturing applications.

Operators benefit from an easy-to-use interface and various applications to meet individual requirements. A variety of communication standards, such as USB or RS232, are available to connect printers and barcode scanners or to download production data or integrate your scales into your system.

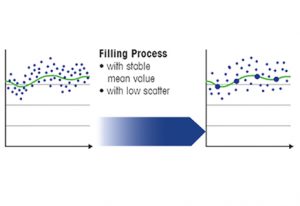

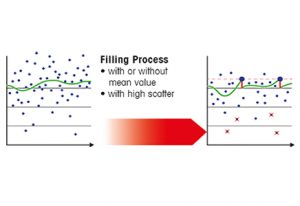

The quality of industrial filling processes varies from 'stable and easy to control' to 'high scatter and difficult to control'. METTLER TOLEDO has suitable SPC or SQC products to ensure systematic monitoring and control of your filling processes. Regardless of the difficulty, the MT products will help you to maintain legal compliance as well as control expensive waste through overfilling and get full control of your profitability. In addition conformance with internal and external standards, like GMP and IFS, is assured.

As a compact single station application or as an element in the network of your QA system, it records your production data. Your processes are clearly documented and traceable.

With manual or automatic control and trend control, trends of the product weight are monitored at regular intervals. Deviations in the filling process are identified and sent either manually or by a control pulse to the filling installation.

The checkweigher can be integrated in your production and checks all products. TU1 violations are limited to the legally admissible percentage. TU2 violations are discarded completely.

The consumer should have access to safe medications, medical devices and services through processes that are understood and controlled, and therefore reproducible. These claims are contained in healthcare regulations and laws worldwide.

Gravimetric level control is one of the most accurate inventory control methods available for measuring high-value solids, liquids and even gases inside tanks. Tank load cell is placed outside of the tank, which makes them superior to other measuring methods for aggressive, hot, frozen, non-free-flowing or non-self-leveling materials. Measuring results are not impacted by tank shape, load cell materials or process parameters, such as temperature or material viscosity.

Most tanks holding 10 kilograms to 1,000 tons or more are mounted on compression load cells or compression weigh modules for weighing. The RockerPin ensures the best accuracy in case of thermal expansion or contraction. Compression weigh modules are ideal for turning tanks into tank scales. In addition, smaller tanks can be mounted on bench or floor scales, which is convenient for legal-for-trade applications.

Tanks or hopper scales can be suspended from tension load cells or weigh modules, with accuracy similar to that achievable with compression systems. This mounting method can be convenient if an overhead structure already exists, or if the ground space under the scale must be kept clear. It is applicable for scales with capacities of approximately 20 kilograms (45 lbs.) to 30 tons.

Outdoor tanks must have safety features to protect the load cell during installation and operation. Tanks are exposed to wind forces. This requires features for weigh modules to cope with uplift forces on one side and extreme load on the other. Temperature changes can result in expansion and contraction of the support structure. Our weigh modules are designed to cope with such circumstances.

Weigh modules with POWERCELL® technology reduce downtime with predictive maintenance. A run-flat function allows you to continue a batch in the event of a damaged load cell or a broken connecting cable. A daisy-chain-type network technology with plug-and-play connectors eliminates the need for junction boxes, which can be prone to damage. The CalFreePlus™ feature eliminates need for re-calibration in the event the cables or load cells have to be replaced.

METTLER TOLEDO weigh modules are designed to mitigate uplift forces resulting from wind and earthquakes and temperature-related expansion and contraction of the tank's support structure. We perform Finite Element Analysis on mechanical parts and perform tests to expose even heavy-capacity weigh modules to real-life conditions with full loads.

Weighing equipment, used in continuous wet and harsh environments or exposed to regular cleaning procedures, needs specific protection technologies. Water and humidity, when penetrating a terminal or a load cell, can damage electronic parts, cause corrosion and may lead to incorrect weighing results or a break down. Furthermore, remaining water or humidity on the product contact surface causes an increased potential for bacteria contaminations.

METTLER TOLEDO offers dedicated weighing solutions suitable for wet and harsh environments. These solutions include long-lasting equipment, which are rated according to highest ingress protection ratings. An enclosure protected with IP69k must not only be dust-tight, but it must also able to withstand high pressure and steam cleaning.

METTLER TOLEDO's preferred construction material for scales used in wet and harsh environments is stainless steel. Our offering includes 304L steel quality and 316Lfor enhanced corrosion resistance that provides a long service life.

Reduced contamination; fast and efficient cleaning procedures - Equipment used for food processing must be designed and installed according to sound sanitary design principles. We offer dedicated solutions, designed in accordance with leading hygienic guidelines, such as National Sanitation Foundation (NSF) or European Hygienic Equipment Design Group (EHEDG). This ensures efficient and thorough cleaning.

Precise scales are the foundation for producing the right colors. Dedicated refinish solutions combine high-performance weighing with a truly industrial design, delivering stable and accurate weighing results under the demanding conditions in an automotive body shop.

Global approvals allow use in hazardous areas and for legal-for-trade applications. Standardized communication protocols and interfaces make integration into paint mixing software easy.

We offer a refinish scale for every need and budget.

Equipment that handles bulk food materials, such as grain, cereals, sugar, feed or oil seeds, has to withstand harsh conditions. METTLER TOLEDO's filling, batching, tank and vehicle weighing solutions are designed to provide accurate weighing results to increase process efficiency and reduce bulk waste to the absolute minimum.

Equipment for the manufacturing of building material and mining facilities have to cope with temperature changes, including strong wind and thunderstorms. Weighing equipment from METTLER TOLEDO allows expansion and contraction of support structures to ensure accurate weighing regardless of weather conditions. POWERMOUNT® load cells withstand lightning and submersion in water.

Equipment weighing in waste-handling facilities, and especially in steel-recycling melting, has to withstand heat, shock loading and overload situations. Vibrations generated by material handling from cranes and shredders are very common. Sophisticated filter technology inside weighing terminals and transmitters ensure stable and reliable weight results.

Gravimetric level control is ideal for aggressive, hot, frozen, non-free-flowing or non-self-leveling materials because load cells are outside of the tank. Measuring results are not impacted by tank shape, temperature or material viscosity. Our weigh modules with POWERCELL® technology reduce downtime with predictive maintenance. The CalFreePlus™ feature eliminates need for re-calibration in the event the cables or load cells have to be replaced.

Truck weighing is often integral to a company's throughput and profit stream. METTLER TOLEDO truck scales provide leading reliability and accuracy for any application, from standard duty to extreme. Rugged designs provide a long service life, while smart control systems, interface options, and peripherals offer advantages to your business operations. As a global leader in measurement, METTLER TOLEDO has solved many of the shortcomings seen in conventional scales through unique innovations.

METTLER TOLEDO rail scales offer rugged designs for durability in numerous configurations, combined with advanced POWERCELL® weighing technology for lasting reliability and high accuracy. Rail scale systems are available for static weighing, and for weighing rail cars that are coupled together and in-motion. Coupled-in-motion (CIM) rail weighing provides the ability to weigh multiple rail cars and entire trains in a fraction of the time.

Completeness matters for manufacturers of parts, modules and kits to ensure customer satisfaction and to avoid expensive rework or return of delivered goods. But completeness also matters in the production process to avoid adding value to defective semi-finished products in subsequent manufacturing steps. Weighing is a simple and fail-safe method for in-process or end-of-line quality control where high-precision scales can detect deviations of 0.001 percent within a split of a second.

Cavities, missing sections in complex structures and density deviations harm quality of tool-shaped parts from injection molding, die casting, powder-metal pressing, sand casting and stamping. The smallest weigh deviations can identify potentially defective products that need further inspection. METTLER TOLEDO has weighing technology with repeatable resolution of up to 4 million points to reliably detect smallest deviations.

Repair, toy or mounting kits often consist of very small and very large parts of different materials, including documentation. Visual completeness control is not effective for checking completeness of parts inside non-transparent packages or when parts are stacked. High-precision weighing can verify completeness despite poor visibility. METTLER TOLEDO offers many solutions from static scales, conveyor scales or weigh modules to incorporate into a machine.

Functionality tests of gear boxes, ball bearings or electromechanical devices do not always detect all the errors that might affect their lifetime. Incorrect oil quantity or missing parts often pass unnoticed in short-term functionality tests. Weighing is a simple-to-apply method for a complementary completeness check, even for products that include movable elements. High-capacity weighing with the highest resolution allows verification of even heavy products.

In manufacturing of pharmaceuticals and cosmetics, verifying volumetric filling by weight is the preferred method because it is directly traceable to a standard. However, the method of gravimetrical quality control is not limited to the quantity of the product. It also verifies presence of accessories. such as spoons and cups or brushes. Our weighing technology combines 100% control and high throughput.

Weight is an important quality parameter for tablets and capsules. Manufacturers either test samples or every tablet. METTLER TOLEDO has dedicated ultra-small weigh modules for compact instruments for sample testing or machines for high throughput when 100-percent control is required.

Products, such as solar wafers, go through several manufacturing steps in which material is added or subtracted. Simple weighing before and after treatment is all that is needed for in-process quality control. High-precision weighing is a simple non-destructive method to verify coating or etching processes. METTLER TOLEDO has a global team of experts that support machine builders and end users in applying weight for manufacturing of all types of electronics.

Accurate weighing helps you manage raw materials, ensure compliance with regulations and improve your product quality. Our high-precision weighing solutions offer industry-leading metrological performance and ensure consistent weighing results when tolerances are tight.

High accuracy weighing scales with a large weighing capacity help improve the effectiveness and efficiency of many weighing processes. For example:

The load cell, with Monobloc technology, is at the core of our high-precision weighing platforms and guarantees the highest accuracy and reliability. The robust load-cell housing features integrated overload protection and durable mechanical interfaces. This ensures stable weight values for many years of intensive use.

The innovative lever-system design of our high-precision floor platforms ensures that the weight is transferred accurately from the load plate to the load cell—even under rough conditions. External impacts such as overload, side forces or vibrations are eliminated through a multi-level protection system.

We offer a range of high-precision bench and floor scales as well as weigh modules and load cells for all kinds of weighing processes. High-precision solutions are available for manual weighing and fully automated applications that require easy and direct integration of the weighing device.

When the precision of your weighing application is critical, regular verification of the measurement accuracy is essential. Watch this video to learn why calibration of the weighing equipment according to your own process tolerances is important. Find out how precision scale decimal can help you meet your quality requirements and save costs.

Truck weighing is often integral to a company's throughput and profit stream. METTLER TOLEDO truck scales provide leading reliability and accuracy for any application, from standard duty to extreme. Rugged designs provide a long service life, while smart control systems, interface options, and peripherals offer advantages to your business operations.

As a global leader in measurement, METTLER TOLEDO has solved many of the shortcomings seen in conventional scales through unique innovations.

Upgrades are also available to retrofit scales from many manufacturers to advanced POWERCELL® weighing systems. This is often done to solve issues with reliability, accuracy, lightning, moisture, and more. DataBridge™ scale management software is a powerful addition to any vehicle scale for easy and professional management of weighing transactions.

Comprehensive truck weighing solutions from METTLER TOLEDO provide advantages for years to come, resulting in a great return on your investment.

METTLER TOLEDO rail scales offer rugged designs for durability in numerous configurations, combined with advanced POWERCELL® weighing technology for lasting reliability and high accuracy.

Rail scale systems are available for static weighing, and for weighing rail cars that are coupled together and in-motion. Coupled-in-motion (CIM) rail weighing provides the ability to weigh multiple rail cars and entire trains in a fraction of the time.

METTLER TOLEDO also offers combination scales designed to weigh both rail cars and over-the-road trucks on a single scale.

Custom-engineered rail solutions can meet the needs of large or special projects with unique requirements for configurations and integration.

Upgrades are also available to improve the performance of existing rail scales. This can include converting older mechanical lever-style rail scales to modern load cell systems as a cost-effective alternative to a new scale.