METTLER TOLEDO Forklift scales is a cost effective solution to speeding up your pallet weighing processes by weighing as you drive for improved productivity and revenue recovery. Designed for tough industrial environments, our forklift scales set the standard for reliability, safety and accuracy in heavy-use applications, with local and International Weights and Measures Approvals that guarantee weighing quality.

| Capacity | 1,500 / 2,000 / 3,000 / 5,000 kg 3,000 / 5,000 / 7,500 / 10,000 lbs |

| Resolution | 1,000~1,500e |

| Certificated temperature | ‘-10 C to 40 °C / 14 to 104°F |

| Stable Weighing Time | 1-2 seconds |

| Angular Compensation Range | Pitch ±5°, Roll ±3° |

| Overload Safe overload | Safe overload 150% Limited Overload: 300% |

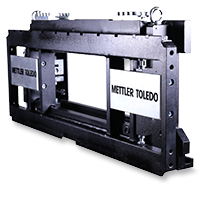

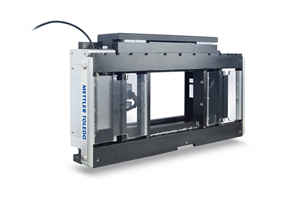

| Material | Steel |

| Capacity Loss | ~15% of forklift capacity |

| Forklift Mounting | Fits ANSI/ITSDF Class II / III / IV Carriages |

| Terminal | IND236 |

| Loadcells | TSH Loadcells |

| Connections | DB9 cable or a Bluetooth dongle |

Features & Benefits

- Angular Compensation Technology

On the side of weighing carriage, there is an angular sensor with anti-vibration functionality for onboard weighing. This angular sensor, combined with a dedicated algorithm, compensate for the uneven surface and maintain weighing accuracy. - Eccentric Adjustment Function

The weighing carriage has two load-cells inside and they help each other to balance the load from side to side. At the same time, the flexture design keeps the balance from back to front. This maintains weighing accuracy regardless of weight distribution. - 3-Point Suspension Technology

There are 3 touch-points on the back of the VFS120 carriage forming a triangle to allow the scale to be in constant contact with the forklift. No other mechanic parts touch with the fork-carriage except for the 3 points and mounting brackets after installation. - High Visibility Windows

Designed based on the needs and habits of forklift drivers, the scale provides good visbility through open windows in the middle and sides of the weighing carriage.