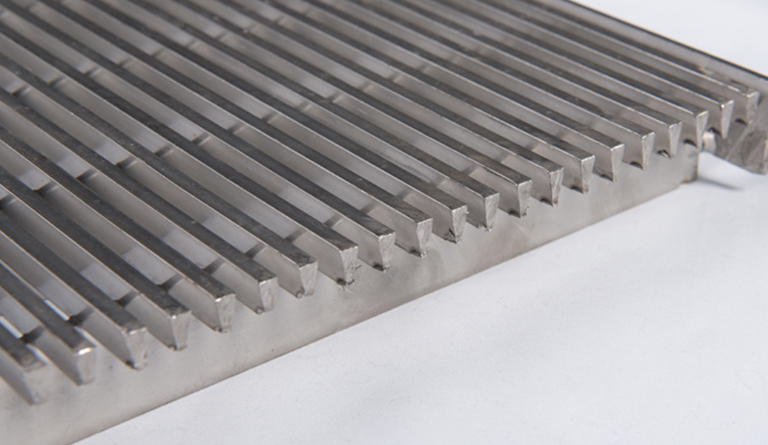

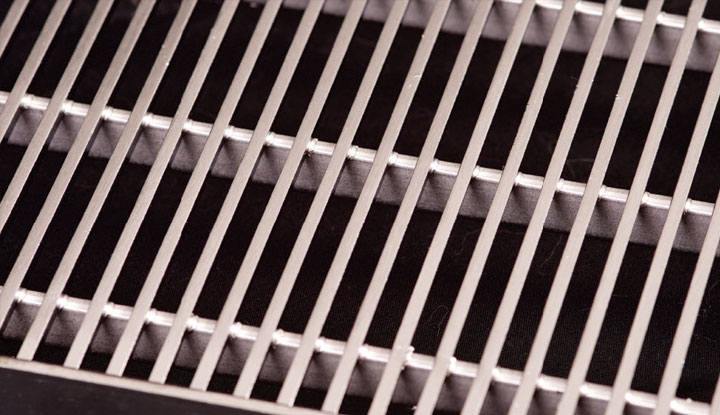

Wedge wire consists of surface profiles, usually V-triangular shape, tig welded onto support profiles. The V wire is used to construct a welded wedge wire screen, this is both robust and extremely accurate.

Normally manufactured from stainless steel, wedge wire comes in many forms, these include flat panels, curved panels, segments and sections. They form floors i.e. for breweries, discs and drums for filtration, in the food washing, food processing and sugar industries. Welded wedge wire is used for many different types of filtration, solid-liquid separation, classification, coal, dewatering, and concentration, regardless of location or industry.

Our wedge wire is a multipurpose screen which is tough, has huge clogging resistance and is extremely durable. It is available in a cylindrical form known as ‘slotted tube filters’. It performs extremely well in applications requiring accuracy as well as strength.

Wedge wire is suitable for maintenance-free situations and high-pressure applications. Reinforcements can be added if required. This provides a strong and cost effective wedge wire screen. Our wire can also be made into tubes and cylinders, with radial or straight slots. The screen surface is either on the inside or the outside of the cylinder. This is to give out-to-in, or flow in-to-out. Welded wedge wire is made in stainless steel grade AISI 304, but other grades are also available.

We were pioneers in the development of wedge wire screens. In recent years a demand has grown for wedge wire assembled by welding, in contrast to the looped method. We have met this demand with the very latest in TIG welding technology. Using specially developed machinery and advanced automatic welding our welded type screens offer a wide range of apertures with clear and unobstructed open area. This latest development uses 6.35 mm diameter crossrods or up to 25 x 6 mm flat bars welded directly to the profile wires. Cross rod pitch can be varied to suit the application.